Add to Cart

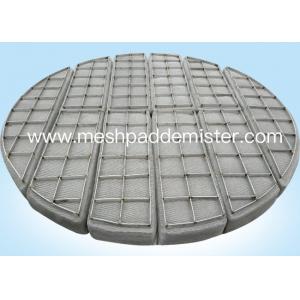

Wire mesh demister used in knock out drum mist eliminator specification

Wire mesh demister used in knock out drum mist eliminator specification

Wire Mesh Demister Standard Specification (part):

1.General

1.1Scope

A.This Standard Specification covers the general requirements for design, construction, fabrication, and material of Mist Eliminators specified in XXX Project Specifications.

B.Exceptions or variations shown in the Project Specifications take precedence over requirements shown herein.

1.2References

Unless noted below, use the edition and addenda of each referenced document current on the date of this Standard Specification. When a referenced document incorporates another document, use the edition of that document required by the referenced document.

A.American Society for Testing and Materials (ASTM) A-478, Specification for Chromium-Nickel Stainless and Heat-Resisting Steel Weaving and Knitting Wire.

B.ASTM B-164, Specification for Nickel-Copper Alloy Rod, Bar, and Wire.

2.Design

2.1General

A.Size, style, thickness, configuration, and materials are specified in XXX Project Specification – Vessels.

B.Mist Eliminator styles are defined as follows:

Wire Mesh Demister Styles:

| Style | Material | Density lb/ft3 (kg/m3) | Wire Diameter Inches (mm) |

| A | Metallic | 9 (144.2) | 0.011 (0.28) |

| B | Metallic | 5 (80.1) | 0.011 (0.28) |

| C | Metallic | 12 (192.2) | 0.011 (0.28) |

| D | Polytetrafluroethylene (PTFE) | normal | 0.012 (0.30) |

| F | Polypropylene | normal | 0.012 (0.30) |

| G | Metallic | Variable 5 (80.1) - 9 (144.2) | 0.011 (0.28) |

| V | Metallic | Other | normal |

C.Style G is a mesh blanket having a variable knitted density. The vapor inlet section is the least dense and the outlet section the densest. Typical inlet/outlet knitted mesh densities are 5 lb/ft3 (80.1) and 9 lb/ft3 (144.2). The customer can require variable density blankets having slightly different knitted densities and wire diameters.

Style V is to be determined by the vendor, based on the process conditions provided by customer. Vendor may determine the mist eliminator type best suited to meet the mist elimination requirement. The selected style may include a mesh pad, vane or a combination of mesh & vanes. The mist eliminator may be oriented vertically, horizontally or at an angle determined by the vendor. A single pad of variable knitted density may also be applied.

Wire Mesh Demister Applications:

Low pressure rectifying column:

Demister increases the purification ratio, enabling a deep cut in residue oil to improve the quality of gas oil. Improved gas oil contains less carbon, asphalt and corrosive metals, increases decomposition capacity by the residue load in the regenerator, and maintains a higher contact reaction to produce a higher gasoline yield ratio.

Lubricant refinery tower:

Demister increases production volume and yield ratio and improves production quality. As a result, the refining of solvent and white clay is practically rationalized.

Distilling equipment:

Improved performance can be obtained in equipment for processing asphalt, organic intermediate substances, fine chemicals, vegetable oil, tall oil, fatty acid, glycerin, lubricant, benzene and propane.

Evaporator:

Demister prevents carryover of valuable products, can be appropriately used for boiler feed water or processes, and produces high quality condensate.

Steam drum:

Demister produces clean and dry solids of less than 0.5ppm and prevents water from flowing back into the turbine.

Absorption tower:

Effective for completely removing all types of flying and accompanying liquids such as absorption oil, glycol and amine dissolution and discharges clean and dry gas. This also improves process efficiency.

Knockout drum

Scrapper thin film evaporator

Separator container and others

Wire Mesh Demister Installation: